Fitter First Year Tools Figure

Flat Drill Fig 1

|

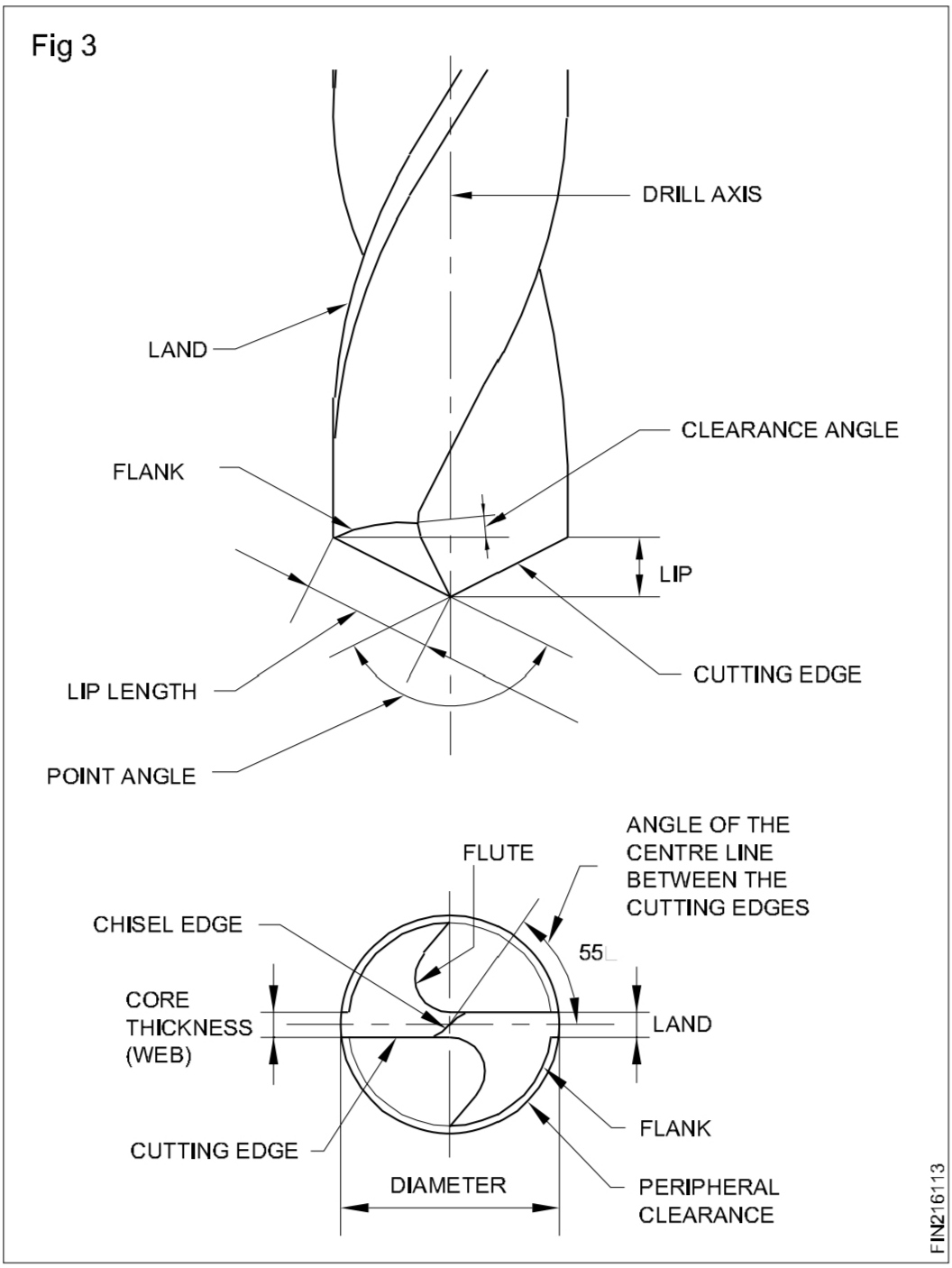

| Parts of twist Drill |

|

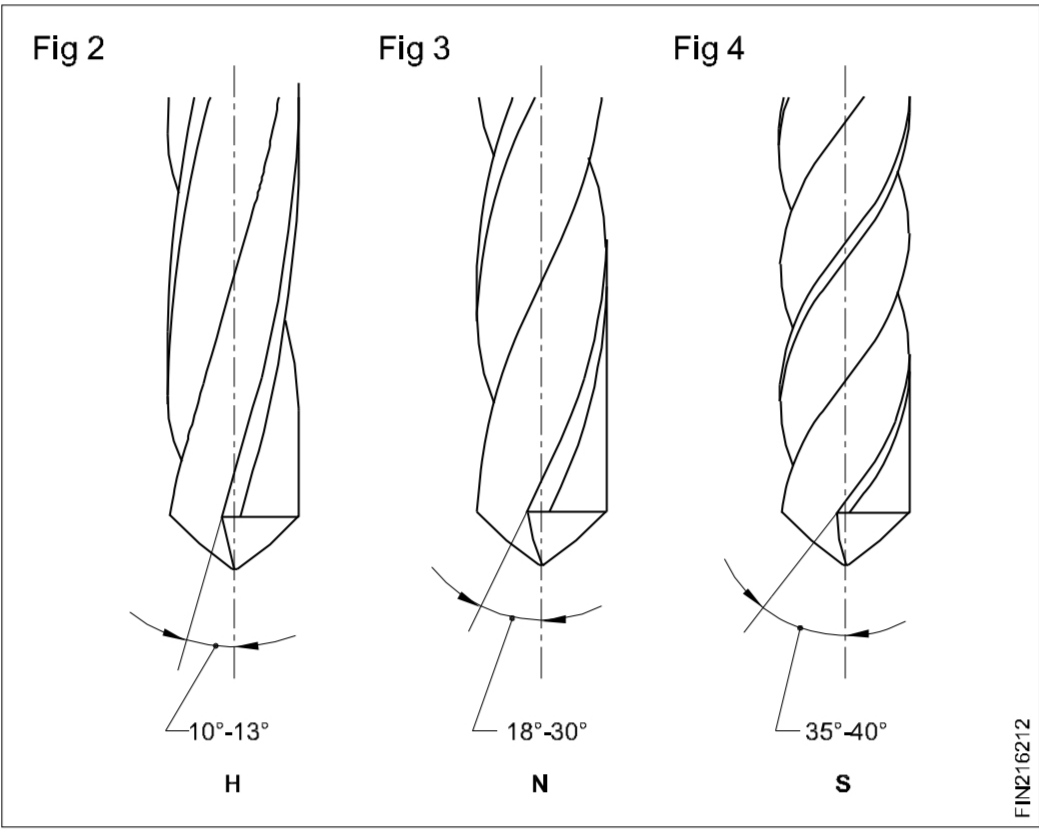

| Helix Angle H, N, S |

|

| Lip Clearance Angle |

Chisel Edge Angle/Web Angle Fig 5

|

| Web Angle |

|

| Drills for different material |

Recommend Cutting Speeds

Drill Chuck Fig 1

Taper Slive And Socket Fig 2

Use a drift to remove drills and sockets from the machine spindle. Fig 3

|

| Drift |

To provide a recess for the head of a countersink screw, so that it is flush with the surface after fixing Fig 1

|

| Counter Shinking |

The commonly used countersinks have multiple cutting edges and are available in taper shank and straight shank. Fig 2

|

| Counter Shinking |

Countersinks with Pilot Fig 3

|

| Counter Shinks with Pilot |

Counter Boring Fig 1

Counter Boring with Pilot Fig 2

Reaming enlarging by finishing previously drilled holes Fig 1

Hand Reamer Fig 2B

Flutes Fig 4

|

| Rake Angle |

Clearance Angle Fig 6

Hand reamer with pilot Fig 4b

Socket reamer with parallel shank (Figs 5a and 5b)

Taper pin hand reamer (Fig 5c)

straight and helical fluted reamers Fig 6

Tags:

FITTER TOOLS